Entre todas las construcciones, hay muchos proyectos de carreteras que requieren pequeñas plantas de asfalto. La conversión frecuente de los sitios de construcción requiere una pequeña planta portátil de mezcla de asfalto con alta movilidad e instalación rápida. Por lo tanto, nuestro fabricante se dedica a la producción de plantas portátiles de procesamiento de asfalto para resolver los problemas. Como uno de los fabricantes avanzados de plantas portátiles de mezclado con equipos de fabricación y trabajadores especializados, hacemos nuestro mejor esfuerzo para producir una planta pequeña y compacta, que sea fácil de ensamblar, desmontar y transportar rápidamente. Las pequeñas plantas portátiles de mezclado de asfalto producidas por nuestro fabricante tienen ventajas superiores de alta flexibilidad, eficiencia y confiabilidad en comparación con otros proveedores portátiles de plantas mezcladoras de asfalto. Nuestra planta portátil de mezclado de asfalto tienecapacidad de 10 ~ 80 t / h , que es muy adecuado para las pequeñas construcciones.

| Modelo | QLB-30 |

| Capacidad | 30t / h |

| Compartimiento agregado frío | 3 |

| Agregado Batcher | 5m3 |

| Poder total | Fuel Oil: 104.5kw; Combustible de carbón: 127.5kw |

| Contenedor de almacenamiento de asfalto terminado | 9t |

| El consumo de combustible | Aceite combustible: 5-7.5 kg / t; Combustible de carbón: 13-15 kg / t |

| Sistema de control | Manual / semiautomático / automático completo; |

| Temperatura del asfalto | 120-180 ° C (ajustable) |

| Modelo | QLB-40 |

| Capacidad | 40t / h |

| Compartimiento agregado frío | 3 |

| Agregado Batcher | 5m3 |

| Poder total | Fuel Oil: 125kw; Combustible de carbón: 169kw |

| Contenedor de almacenamiento de asfalto terminado | 9t |

| El consumo de combustible | Aceite combustible: 5-7.5 kg / t; Combustible de carbón: 13-15 kg / t |

| Sistema de control | Manual / semiautomático / automático completo; |

| Temperatura del asfalto | 120-180 ° C (ajustable) |

| Modelo | QLB-60 |

| Capacidad | 60t / h |

| Compartimiento agregado frío | 3 |

| Agregado Batcher | 5m3 |

| Poder total | Fuel Oil: 157.5kw; Combustible de carbón: 205kw |

| Contenedor de almacenamiento de asfalto terminado | 9t |

| El consumo de combustible | Aceite combustible: 5-7.5 kg / t; Combustible de carbón: 13-15 kg / t |

| Sistema de control | Manual / semiautomático / automático completo; |

| Temperatura del asfalto | 120-180 ° C (ajustable) |

| Modelo | QLB-80 |

| Capacidad | 80t / h |

| Compartimiento agregado frío | 4 |

| Agregado Batcher | 5m3 |

| Poder total | Fuel Oil: 200kw; Combustible de carbón: 276kw |

| Contenedor de almacenamiento de asfalto terminado | 20t |

| El consumo de combustible | Aceite combustible: 5-7.5 kg / t; Combustible de carbón: 13-15 kg / t |

| Sistema de control | Manual / semiautomático / automático completo; |

| Temperatura del asfalto | 120-180 ° C (ajustable) |

Características de las pequeñas plantas portátiles de asfalto en venta

1. La planta portátil de mezcla de asfalto está montada en un remolque móvil , que es conveniente para ser transportado a través del remolque del tractor.

2. La planta portátil de procesamiento por lotes asfáltico tiene un diseño modular, que es conveniente para el transporte.

3. It has compact structure, unique appearance, reasonable design, which is easy for operating and maintaining.

4. The integrated dryer drum and mixer greatly ensures the quality of bitumen mixture.

5. The bag dust catcher can improve material utilization rate, which can save energy consumption.

6. The equipment has noise reducing device, which can reduce noise pollution.

7. Each part of the portable asphalt plant is connected closely, which can largely save occupation areas.

8. The optimized mixing blades with powerful mixing strength make the mixing easy, reliable and efficient.

9. Automatic PLC control and manual control make the operation much easier and safer.

10. The detection and diagnosis function can warn failures as soon as possible, which can reduce maintenance cost.

Specifications of Small Portable Asphalt Plants

| Model | QLB-10 | QLB-15 | QLB-20 | QLB-30 | QLB-40 | QLB-60 | QLB-80 | |

| Capacity | 10t/h | 15t/h | 20t/h | 30t/h | 40t/h | 60t/h | 80t/h | |

| Cold Aggregate Bin | 3 | 3 | 3 | 3 | 3 | 3 | 4 | |

| Aggregate Batcher | 2.3m3 | 2.3m3 | 2.3m3 | 5m3 | 5m3 | 5m3 | 5m3 | |

| Total Power | Fuel Oil | 41.5kw | 54kw | 63.5kw | 104.5kw | 125kw | 157.5kw | 200kw |

| Fuel Coal | 57.5kw | 75kw | 86.5kw | 127.5kw | 169kw | 205kw | 276kw | |

| Finished Asphalt Storage Bin | 2t | 5t | 5t | 9t | 9t | 9t | 20t | |

| Fuel Consumption | Fuel Oil: 5-7.5 kg/t;Fuel Coal: 13-15 kg/t | |||||||

| Control System | Manual/semi-automatic/full automatic; | |||||||

| Asphalt Temperature | 120-180°C (adjustable) | |||||||

| Optional Components | Water dust collector/Bag house dust collector; side aside type finished product bin | |||||||

Details of Small Portable Asphalt Mixing Plant for Sale

1. Cold aggregate container

The portable asphalt mixing plant has equipped with four containers with small volume, which is adaptable to the production capacity. The arrangement of cold aggregate can save occupation space, which makes compact structure. The cone-shaped cold aggregate can ensure smooth discharge.

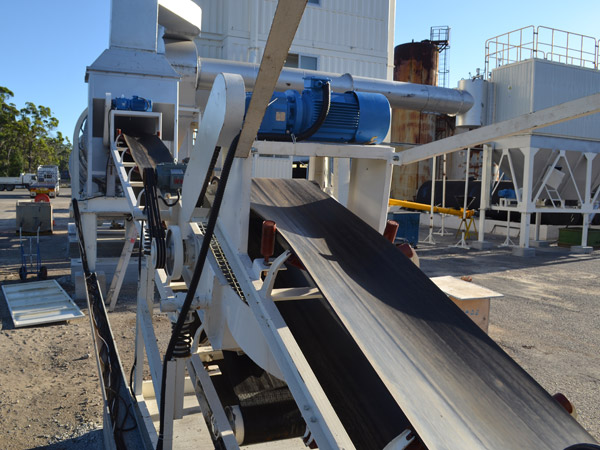

2. Belt conveyor

The belt conveyor has the basic function of transporting cold aggregate to the dryer drum. Besides, there is filter screen mounted on the conveyor. The filter screen is used to rule out the oversized aggregate, avoiding it transported to the dryer drum through belt conveyor, which can reduce heat loss. Under belt conveyor, there is safety protection device. It can be brake in emergency conditions. The equipped cleaning device can ensure no cold aggregate left on the belt conveyor. The conveyor can be folded easily with quick installation and transportation.

3. Drying drum

With our portable asphalt batching plant, there is a chassis for the dryer drum. The chassis device can save time to change sites frequently. It is easy to move with lightweight. The outer of drum is covered with insulating layer to decrease heat loss. It is cast with anti-weary steel alloy to extend service life. The burning area of dryer drum ensures sufficient heat exchange, which can thoroughly dry cold aggregate with high thermal efficiency.

4. Dust remover

The small portable asphalt mix plant has water dust collector and bag dust catcher. The dust collecting system adopts Nomax filter bag. The dust concentration can be guaranteed less than 50mg/nm3, which totally satisfies the national emission standard requirement. The recycled dust can be reused to avoid secondary pollution.

5. Vibrate screen

The vibrate screen is the sieving device to separate hot aggregate according to different particle sizes, which can assure aggregate accurate measurement before mixing. The screen is made up of high strength manganese with reinforced rim, which can prolong the service life. The segmented design is convenient to maintain. In addition, the vibrating screen is tightly sealed without dust overflowing.

6. Asphalt tank

The asphalt tank has insulating layer, which can retain heat for a long time and help save fuel for the bitumen tank burner. Installed on asphalt liquid level and temperature display device, the tank is convenient to operate.

7. Mineral filler unit

Mineral filler unit comes with air compressor unit for freely blowing the minerals into the mixer through the screw conveyor. The bottom of old and new powder silo has arch broken device, which can prevent powder arching efficiently and ensure uniform and continuous powder supply. Vertical and modular powder silo can be installed and transported quickly. The outlet of silo has manual valve, which is convenient to maintain. The intensive storage and discharge of recycled powder can reduce the environmental pollution.

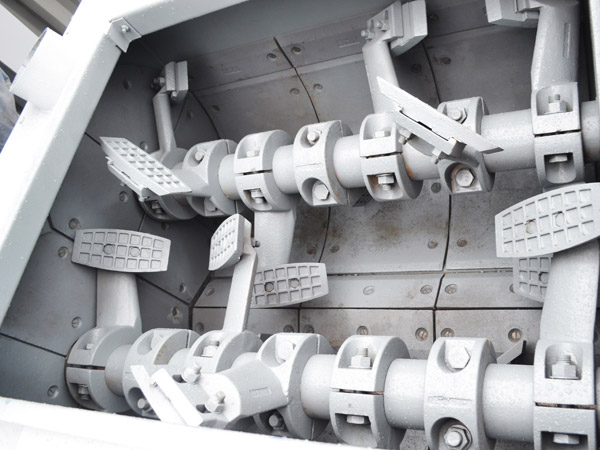

8. Mixer

The small asphalt mixing plant adopts twin-shaft mixer with strong mixing power. The mixing blades and liners use weary-resistant materials with long life span. It takes only 45 seconds to finish one mixing process, which can ensure stable production speed. The maintenance-free pneumatic discharge door can avoid mixture bond and material leakage.

9. Finished products storage bin

It is integrated with the mixing tower. The small area coverage can realize energy conservation and environment protection. The temperature of discharge door can be controlled automatically to prevent bond. The waste can be identified automatically.

Company Information

Nuestro fabricante es el principal fabricante y empresa líder de equipos de construcción de China. Además de la pequeña planta portátil de mezcla, también tenemos muchas plantas de asfalto para la venta , como planta de mezcla de asfalto estacionaria, planta de procesamiento de asfalto móvil , planta mezcladora de tambor de asfalto , mini planta de asfalto, etc. Nuestros productos han sido exportados a muchos países, como Argelia , Pakistán, Brasil, Birmania, Botswana, Ucrania y Tayikistán. Si confías en nosotros, te damos la sincera bienvenida de visitar nuestra fábrica de fabricación.